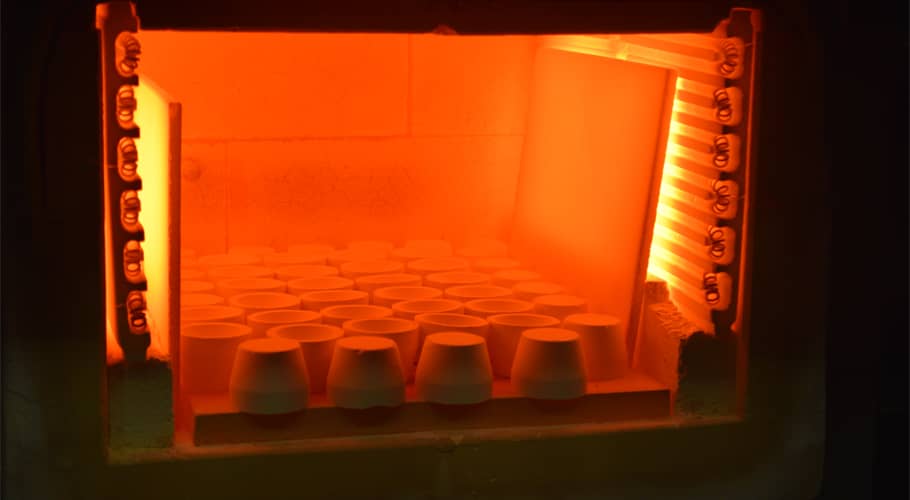

Fire Assay

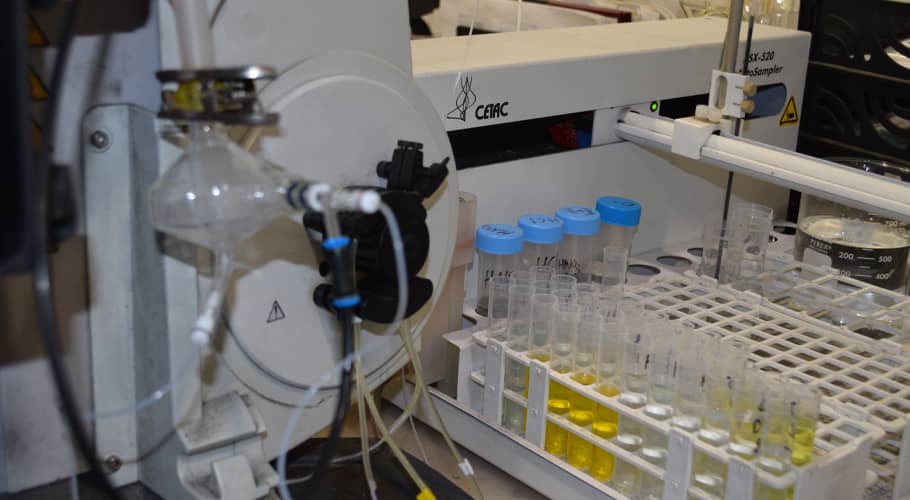

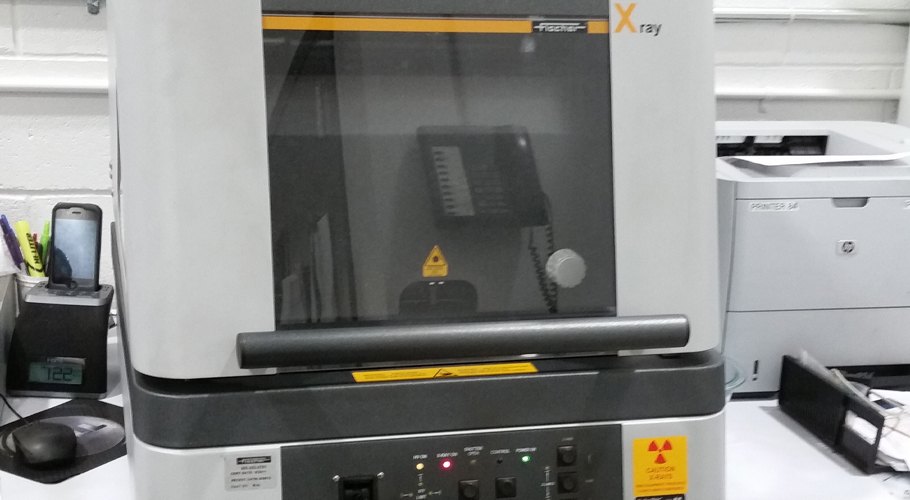

The fire assay procedure is an age-old practice and is most widely accepted as the standard in the jewelry industry when determining the gold and silver content. Making United superior with our speed and accuracy is our state-of-the-art analytical department. We perform three separate fire assays with each individual lot. To insure the maximum returns, we utilize our two-step process of fire assaying and X-ray Fluorescence.